How Oxygen Sensors Monitor Exhaust Gases and Support Engine Control

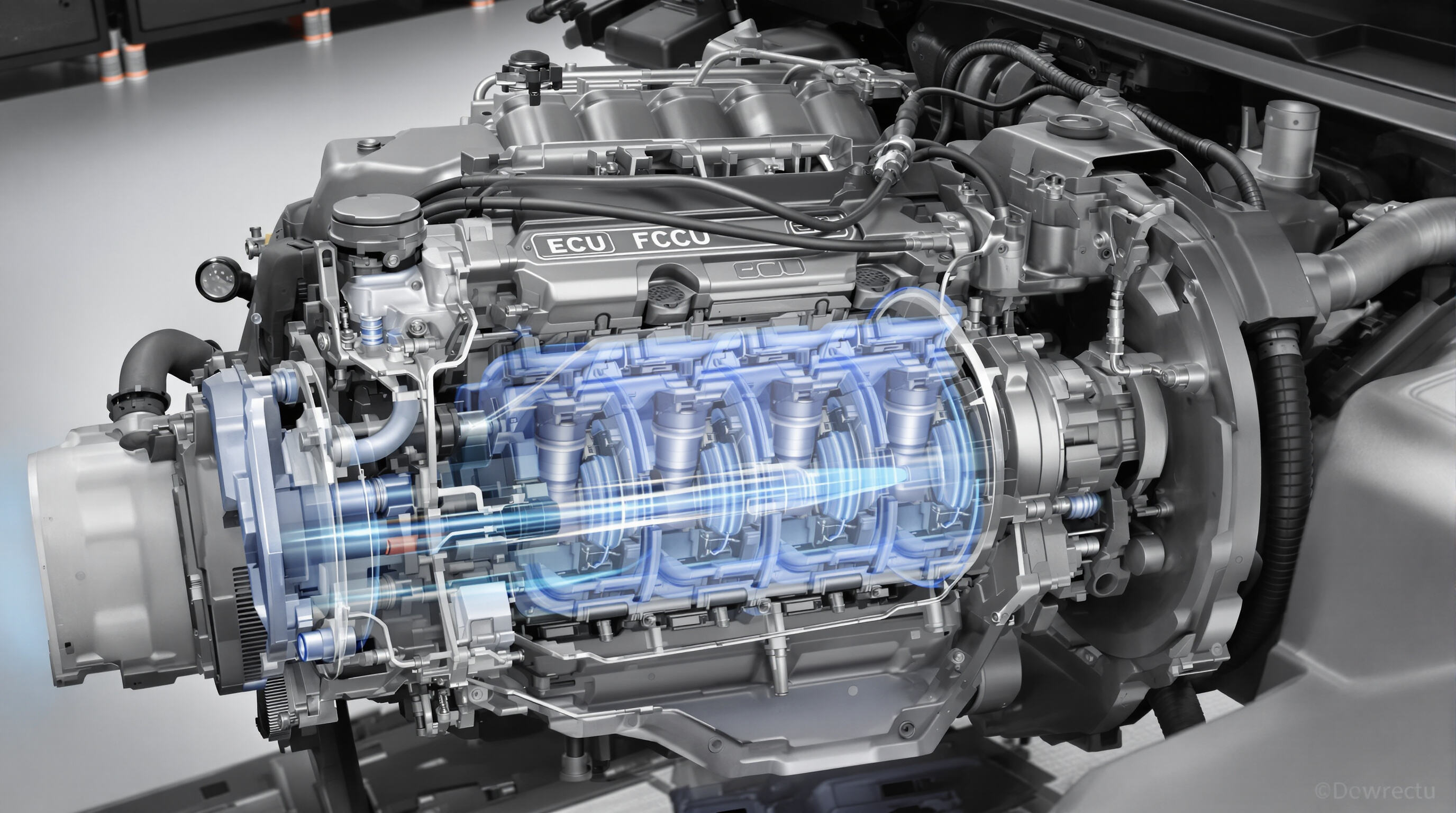

How Oxygen Sensors Measure Oxygen Levels in Exhaust Gases

Oxygen sensors work by looking at how much oxygen there is in the exhaust gases compared to what's in regular air outside the engine. These sensors usually contain either zirconia or titania materials that create electrical signals when they detect differences in oxygen levels between their two sides. When the sensor outputs low voltages around 0.1 to 0.2 volts, that means there's plenty of extra oxygen left after combustion - basically telling us the engine is running too lean. On the flip side, if we see higher readings between 0.8 and 1 volt, this shows very little oxygen remains, which points to a richer fuel mixture. The engine control unit gets these readings instantly and can tweak fuel delivery almost immediately, keeping the combustion process as efficient as possible under varying driving conditions.

Zirconia vs. Titania Sensor Technologies: How They Detect Oxygen Content

- Zirconia sensors are the most widely used, employing a ceramic zirconium dioxide element that generates a voltage in response to oxygen differentials.

-

Titania sensors operate by measuring resistance changes and require an external voltage supply, making them less common and primarily found in select European vehicles.

While both support accurate air-fuel ratio control, zirconia sensors offer faster response times and better integration with modern emission systems.

Real-Time Feedback Loop Between Oxygen Sensor and the ECU

The engine control unit constantly adjusts how much fuel gets delivered based on what it hears from oxygen sensors, doing this around 50 to 100 times every single second. This creates what engineers call a closed loop system where everything works together in real time. Keeping that sweet spot of about 14.7 parts air to 1 part fuel makes engines run cleaner and burn less gas overall. Some research suggests drivers can actually save between 10% and 15% on their fuel bills when these systems work properly. But things go sideways pretty quickly if those sensors start acting up. Once they fail, the ECU has no choice but to switch back to basic preprogrammed settings known as open loop mode. The result? Engines run rougher, pollute more, and guzzle gasoline at an alarming rate until repairs happen.

Narrowband vs. Wideband Oxygen Sensors: Applications in Modern Engines

| Feature | Narrowband Sensors | Wideband Sensors |

|---|---|---|

| Measurement Range | Binary (rich/lean) | Linear (0.5–4.5V range) |

| ECU Adjustments | Basic fuel trim | Precise AFR control |

| Use Cases | Pre-2000 vehicles | Turbocharged/DI engines |

Wideband sensors have become standard in vehicles after 2008 due to stricter emissions regulations. Their ability to provide high-resolution data (0.01–0.02λ) allows for fine-tuned air-fuel control, optimizing catalytic converter performance and supporting advanced engine technologies like direct injection.

Optimizing Air-Fuel Ratio and Combustion Efficiency Through Oxygen Sensing

Oxygen Sensor's Role in Adjusting the Air-Fuel Mixture for Peak Efficiency

Oxygen sensors serve as chemical feedback devices for engines, constantly checking what's going on with oxygen levels in the exhaust so the ECU can adjust how much fuel gets delivered. When these sensors pick up if the air-fuel mix has too much fuel (rich condition) or too much oxygen (lean condition), they allow immediate adjustments towards that ideal 14.7 to 1 ratio most gasoline engines run best at. Getting this right means better combustion happens inside the engine cylinders. The result? More power coming out of the engine block while wasting less energy overall. For car manufacturers and drivers alike, this kind of precision makes all the difference between efficient operation and wasted resources.

Maintaining Stoichiometric Balance With Real-Time Oxygen Sensor Data

In modern vehicles, the oxygen sensor sends voltage updates to the ECU every 100 milliseconds, enabling immediate fuel trim adjustments. This closed-loop control is essential for catalytic converter efficiency–deviations as small as 0.5% from the ideal air-fuel ratio can reduce converter effectiveness by 20–30%, according to research from Tomorrow's Technician.

Impact of Incorrect Air-Fuel Ratios on Engine Performance and Fuel Economy

| Imbalance Type | Effect | Economic Impact |

|---|---|---|

| Too Rich | Increased CO/HC emissions, spark plug fouling | +15-20% fuel consumption |

| Too Lean | Engine knocking, valve damage | $400-$1,200 repair costs |

Prolonged operation with incorrect ratios can reduce fuel economy by up to 18% (SAE 2023) and increase NOx emissions fourfold, accelerating wear and compromising emissions compliance.

Case Study: Fuel Efficiency Gains After Replacing a Faulty Oxygen Sensor

A 2024 fleet analysis revealed that replacing degraded oxygen sensors led to:

- 12–15% improvement in MPG within the first 1,000 miles

- 41% reduction in hydrocarbon emissions

- 27% faster catalytic converter light-off times

These results highlight how sensor maintenance directly enhances fuel efficiency, lowers emissions, and supports long-term system reliability.

Reducing Harmful Emissions: The Oxygen Sensor's Role in Lowering CO, HC, and NOx

How precise Oxygen Sensor data enables reduction of CO, HC, and NOx emissions

Oxygen sensors play a really important role in monitoring emissions because they give ongoing information about what's happening with oxygen levels in exhaust gases. When these sensors work properly, they help the engine control unit keep things running close to that ideal 14.7 to 1 air-fuel ratio. This basically means less HC and CO gets released since the fuel burns more completely. Another benefit comes from keeping combustion temperatures steady. Engines that run this way produce significantly fewer NOx emissions too something like around 63% less than engines where everything isn't properly controlled according to recent EPA data from 2023.

Enabling catalytic converter efficiency through accurate oxygen monitoring

Catalytic converters rely heavily on both upstream and downstream oxygen sensors to get the most out of their job cleaning up exhaust pollutants. The downstream sensor basically checks if things are working right by looking at oxygen levels after the treatment process happens inside the converter. These sensors need to be in good shape for maximum effectiveness. With all sensors functioning properly, these devices can cut down harmful emissions by around 98%. But watch out what happens when those sensors start going bad – performance drops dramatically to about 72% efficiency. That makes a huge difference in how clean our air stays, especially considering how many vehicles are on the road today.

EPA data on emission reductions from properly functioning Oxygen Sensors

EPA testing shows vehicles with fully operational oxygen sensors emit 43% less NOx and 37% fewer hydrocarbons than those with faulty units. This translates to preventing approximately 1.2 tons of ozone-forming pollutants annually per vehicle–making oxygen sensor performance a key factor in improving urban air quality.

Debating sensor over-engineering: Are modern Oxygen Sensors too sensitive for real-world use?

The fuel trim accuracy of wideband sensors sits around 0.1%, way better than the 3% margin found in those old narrowband models we used back in the day. A few mechanics out there actually complain about these sensors being too sensitive sometimes, especially when cars are going through those quick changes in load or speed. They see fault codes popping up before they expect them. But government agencies keep pushing for this level of precision because they need vehicles to hit those tough Euro 7 and EPA Tier 4 requirements. These regulations basically demand that cars stay under 10% emissions variance even after clocking up 150k miles on the road. Makes sense if you think about long term environmental impact versus short term convenience.

Using Upstream and Downstream Oxygen Sensors to Monitor Emissions System Health

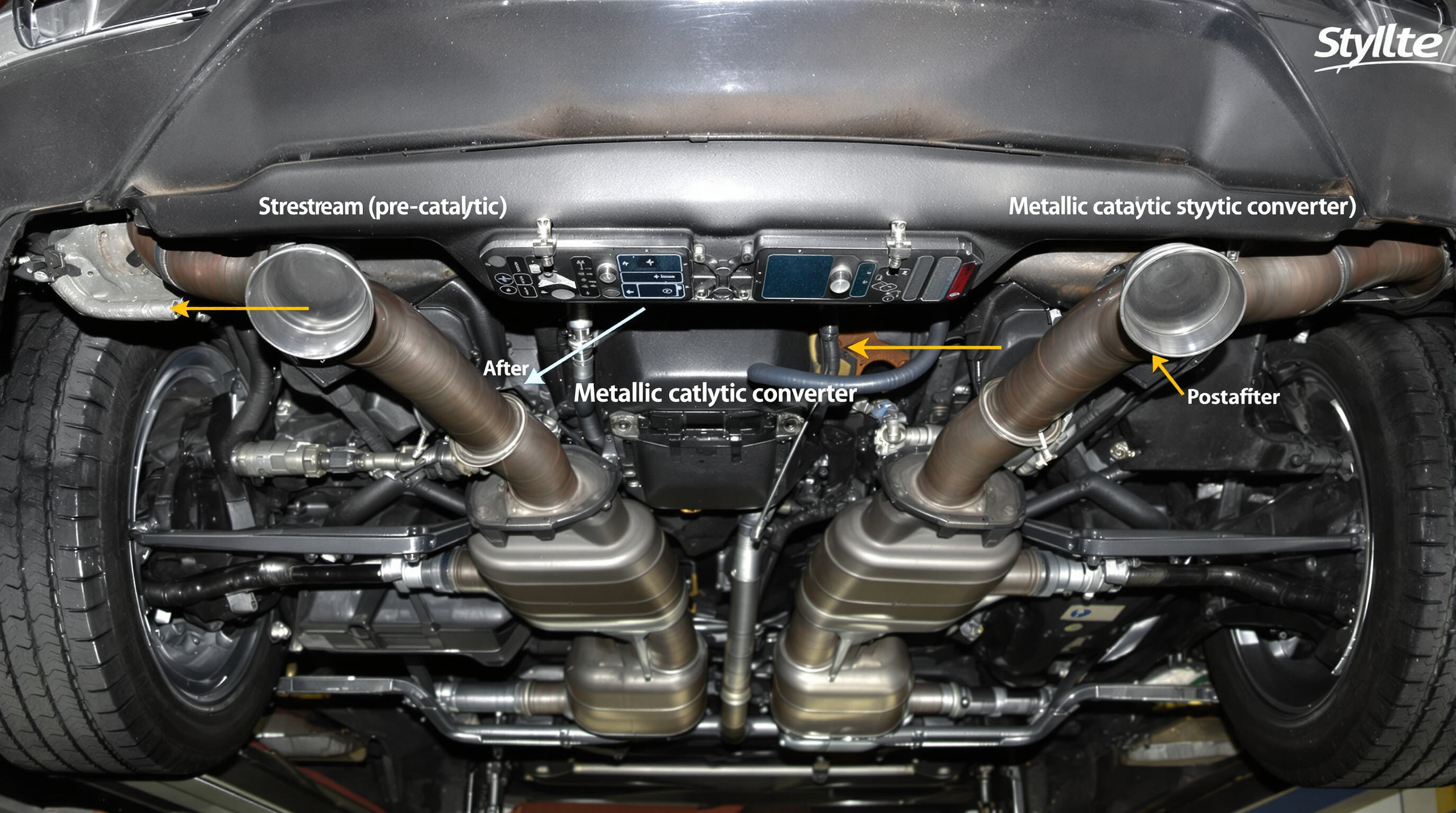

How upstream (pre-catalytic) and downstream (post-catalytic) Oxygen Sensors work together

Today's cars come equipped with two oxygen sensors that help keep emissions under control. The first one sits right before the catalytic converter and does the job of measuring oxygen levels in the raw exhaust gases coming straight from the engine. This information gets sent to the car's computer which then makes instant adjustments to the fuel mixture. There's another sensor positioned after the catalytic converter that checks what comes out on the other side. When everything works as it should, this second sensor gives pretty steady readings because the converter has done its job cleaning up those harmful gases. If there are wild fluctuations in the first sensor's readings while driving but nothing strange shows up in the second, that tells the onboard computer something might be wrong with how the whole emission system is working together.

Diagnosing catalytic converter efficiency using Oxygen Sensor signal comparison

The catalytic converter works by smoothing out those wild oxygen swings, so we see a much steadier signal downstream usually below 0.5 volts instead of the up and down pattern seen upstream between 0.1 and 0.9 volts. Mechanics know something's wrong when they notice both sensors showing similar wiggles this means the converter isn't doing its job properly and will set off codes like P0420 on most modern cars. According to studies, around eight out of ten catalytic converter issues get spotted first by looking at these oxygen sensor signals. That early detection actually stops roughly three tons worth of extra nitrogen oxide pollution every year for just 10,000 vehicles on the road.

Oxygen Sensor data as a key indicator of long-term emissions system performance

When the downstream sensor voltage stays consistently more than 0.3 volts away from normal levels, studies show catalysts tend to break down about 19% quicker according to research published by SAE International back in 2022. Keeping an eye on how quickly these sensors respond and whether their signals stay stable makes all the difference when it comes to maintenance planning. With proactive monitoring, emission systems last roughly 28% longer than if we wait until something breaks before fixing it. The regulations changed quite a bit since around 2008 actually. Most gas powered cars now need two oxygen sensors instead of just one, which covers about 98% of models out there on the road today. This helps manufacturers meet those ever tightening emissions standards over time.

Oxygen Sensor Performance and Compliance in Vehicle Emissions Testing

Link Between Oxygen Sensor Function and Passing State Emissions and Smog Checks

Having a working oxygen sensor makes all the difference when it comes time for those emissions tests. The sensor helps keep the engine control unit (ECU) running combustion just right, so hydrocarbons stay under 4 grams per mile and nitrogen oxides don't go past 0.7 grams per mile. These are pretty much the magic numbers according to EPA Tier 3 regulations from 2023. Things get messy though when these sensors start to wear out. Once they do, the ECU has no choice but to rely on basic fuel settings, which can push carbon monoxide levels way over 5%. That's way higher than normal engines typically run at between 0.1% and 0.3%.

How a Failing Oxygen Sensor Leads to Higher NOx Output and Test Failure

When sensors go bad, they really mess with how well catalytic converters work. Some tests from CARB show emissions of NOx can jump as much as three times what they should be. The problem gets worse when sensors respond slowly. This leads to either too much fuel (rich mixture) or not enough (lean mixture). Rich mixtures mean more unburned gas hanging around, and lean mixtures actually make engine temps spike higher than normal. Both situations help create those nasty NOx pollutants we all try to avoid. Most drivers will start noticing something's off long before their car fails inspection. Rough idling is common, along with that distinct smell similar to rotten eggs. These signs act kind of like red flags telling owners there might be trouble ahead with their emission controls.

The Growing Role of OBD-II and Oxygen Sensor Data in Automated Emissions Programs

Forty-one U.S. states now use OBD-II data during emissions testing, shifting from traditional tailpipe measurements to real-time system diagnostics. This evolution enables continuous monitoring and earlier detection of developing issues.

| Monitoring Aspect | Traditional Tailpipe Test | OBD-II Data Analysis |

|---|---|---|

| Testing Frequency | Biennual snapshots | Continuous monitoring |

| Fault Detection | End-stage failures | Early sensor degradation alerts |

| Compliance Focus | Emission levels | System responsiveness |

California’s Tech-Enhanced Smog Check program (2025) exemplifies this trend, using sensor readiness codes and voltage pattern analysis to replace static emission tests in major urban areas, improving accuracy and enforcement of long-term compliance.

Frequently Asked Questions (FAQ)

What is the role of oxygen sensors in a vehicle?

Oxygen sensors measure the oxygen levels in exhaust gases to help maintain optimal air-fuel ratios for efficient combustion and reduced emissions.

How do zirconia and titania sensors differ?

Zirconia sensors generate voltage based on oxygen differential, while titania sensors measure resistance changes and require external voltage supply.

What happens when an oxygen sensor fails?

When oxygen sensors fail, the ECU shifts to open loop mode, causing rough engine operation, increased pollution, and reduced fuel efficiency.

Why are wideband oxygen sensors used in modern engines?

Wideband sensors offer precise air-fuel ratio control suitable for stringent emissions standards and high-performance engines.

Table of Contents

- How Oxygen Sensors Monitor Exhaust Gases and Support Engine Control

- Optimizing Air-Fuel Ratio and Combustion Efficiency Through Oxygen Sensing

-

Reducing Harmful Emissions: The Oxygen Sensor's Role in Lowering CO, HC, and NOx

- How precise Oxygen Sensor data enables reduction of CO, HC, and NOx emissions

- Enabling catalytic converter efficiency through accurate oxygen monitoring

- EPA data on emission reductions from properly functioning Oxygen Sensors

- Debating sensor over-engineering: Are modern Oxygen Sensors too sensitive for real-world use?

- Using Upstream and Downstream Oxygen Sensors to Monitor Emissions System Health

- Oxygen Sensor Performance and Compliance in Vehicle Emissions Testing

- Frequently Asked Questions (FAQ)