Enhanced Engine Performance Through Precise Suction Control

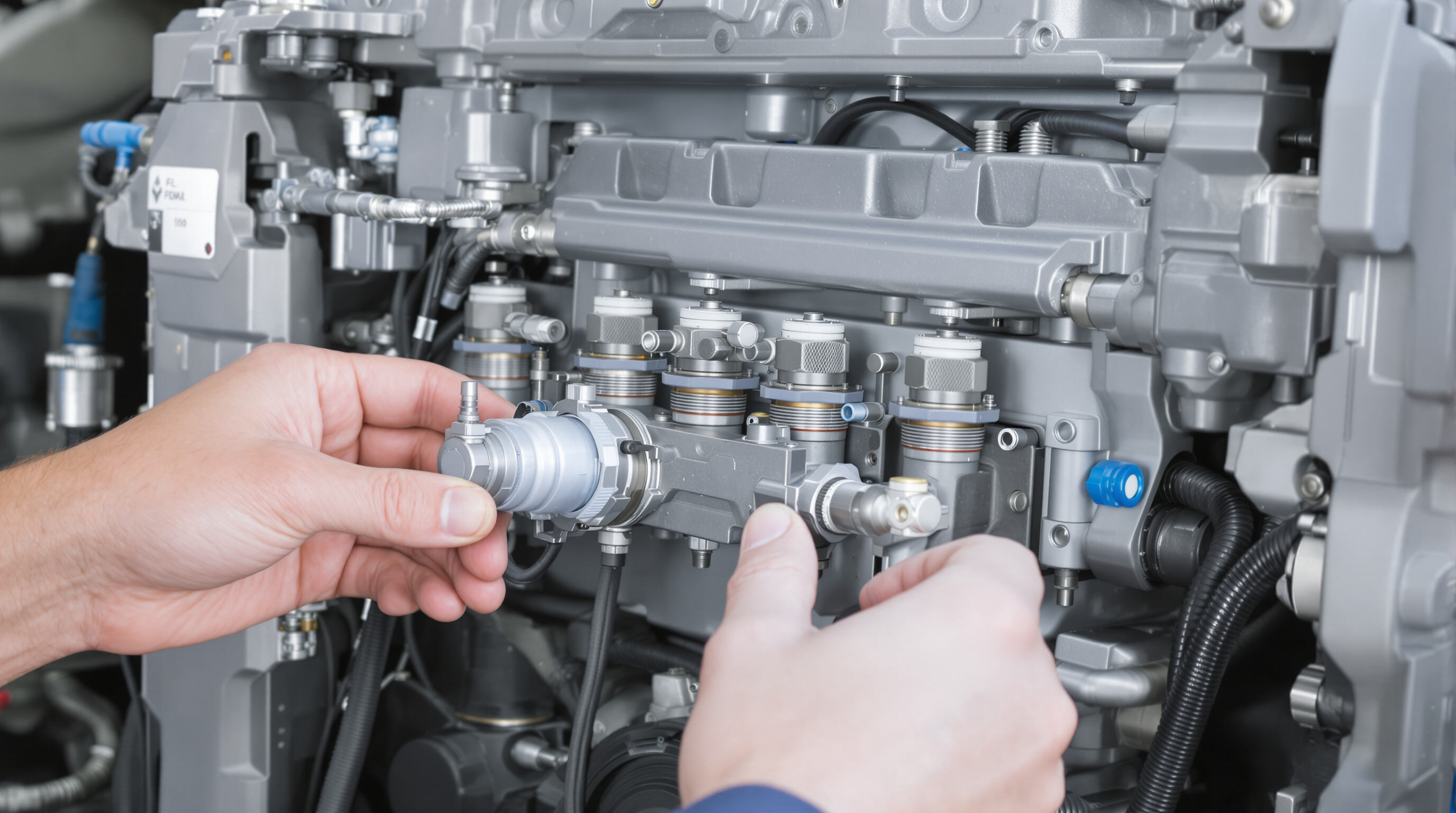

Function of Suction Control Valve in Diesel Engines

Suction control valves (SCVs) manage how much fuel gets into those high pressure pumps down to the micron level, which makes a big difference in how efficiently diesel engines burn that fuel. These valves adjust the amount of fuel going in depending on things like engine speed and what kind of workload the vehicle is handling. What this means is they keep the right mix of air and fuel going throughout all sorts of driving situations. The system works pretty well too it stops excess fuel from getting injected when the engine is just idling around, but still delivers enough juice when someone really needs power. According to research from SAE International back in 2023, these smart adjustments can cut particulate emissions by as much as 18% in newer engine models.

Integration of SCV in Modern Engine Management Systems

The modern engine control unit, or ECU for short, works closely with several components at once. It coordinates the sequential combustion valve operation while monitoring turbocharger boost pressure levels and managing exhaust gas recirculation. All this happens thanks to information gathered from around twelve different sensors throughout the system, such as those tracking crankshaft position and measuring incoming air mass flow rates. These adjustments happen roughly every 0.02 seconds, which makes it possible to keep emissions under much better control than before. Manufacturers have found that integrating these systems helps them comply with the strict Euro 7 regulations currently in place. Field testing conducted recently indicated about a 12 percent drop in nitrogen oxide emissions when compared against older mechanical setups according to a study published in the Journal of Automotive Engineering back in 2023.

Impact of SCV Performance on Fuel Efficiency and Engine Power

Precision SCVs significantly influence fuel economy and power output:

| SCV Condition | Fuel Efficiency | Power Output | Maintenance Frequency |

|---|---|---|---|

| Optimal | +7-9% | +15 HP | 12,000-hour intervals |

| Worn | -14% | -22 HP | 4,000-hour intervals |

| Failed | N/A | System shutdown | Immediate repair |

According to the 2024 Heavy-Duty Engine Efficiency Report, SCV optimization accounts for 40% of the 4% overall fuel economy improvement in current diesel powertrains. Electronically controlled SCVs also deliver 23% faster throttle response.

Trend Toward Electronically Controlled Suction Valves

A lot of industries are moving away from old fashioned pneumatic systems toward servo motor driven SCVs these days. What's really impressive is how accurate they can be - we're talking about positioning down to 0.001 inches, which is actually three times better than what was possible before. These newer valves come equipped with sensors built right in, allowing for predictive maintenance capabilities. The sensors can spot signs of wear long before any actual problems show up on the surface, sometimes as much as 500 operating hours ahead of time. With environmental regulations getting stricter all the time, most manufacturers are adapting fast. According to Diesel Progress International from last year, around four out of five new heavy duty engines already incorporate self calibrating SCVs that have smart algorithms working behind the scenes.

Superior Flow and Pressure Control in Fluid Systems

Precise Dosing and Flow Control in Critical Applications

Modern SCVs deliver ±1% dosing accuracy in pharmaceutical and chemical processing (ISPE 2023), preventing overflows in fuel systems and ensuring consistency in food production, where even a 2% flow deviation can spoil entire batches.

Enhanced Flow and Pressure Control in Fluid Systems

Advanced SCVs work with IoT-enabled pressure sensors to maintain stable performance across 50-800 PSI ranges. This prevents pump cavitation in water treatment and enables 17% faster fluid transfer in hydraulic systems compared to mechanical valves. Smart algorithms automatically adjust for viscosity changes in temperature-sensitive processes like resin molding.

Improved Safety and Efficiency in Fluid Control Systems

High-performance SCVs reduce pressure-related equipment failures by 63% in mining (NFPA 2024 data), with dual redundant seals minimizing leaks in hydrocarbon applications. Energy recovery features cut power consumption by 22% in continuous-operation pumping stations, while auto-calibration eliminates the need for manual adjustments during 24/7 operations.

Long-Term Durability and Reliability of High-Quality SCVs

Lifespan and Durability of Suction Control Valves Under High Stress

Premium SCVs endure up to 2.5 times more cyclic stress than budget alternatives. Constructed with hardened steel cores and ceramic-reinforced seals, they maintain integrity through 250,000+ duty cycles (Pump Systems Analysis 2023). This durability directly reduces replacement costs in high-uptime systems.

Material and Chemical Compatibility in Harsh Operating Environments

Modern SCVs use nickel-alloy bodies and PTFE-coated components to resist acidic fluids (pH <3), saltwater corrosion, and abrasive slurries. These materials enable reliable operation from -40 °F to 500 °F, outperforming standard stainless steel by 72% in extreme thermal cycling tests (Fluid Dynamics Journal 2024).

Failure Analysis: Low-Quality vs. High-Quality Suction Control Valves

| Failure Mode | Budget SCVs | Premium SCVs |

|---|---|---|

| Seal Degradation | 82% within 2 years | 12% within 5 years |

| Body Corrosion | 67% in salty env. | 9% in salty env. |

| Pressure Surge Damage | 41% failure rate | 3% failure rate |

Data from 3,200 valve failure reports (Industrial Maintenance Quarterly 2024)

Balancing Initial Cost and Long-Term System Reliability

Although premium SCVs cost 30-50% more upfront, their 7-10 year service life compared to 18-24 months for low-cost models reduces total ownership costs by 60% in pumping systems. Operators report 89% fewer unplanned shutdowns, confirming the return on investment in quality-driven procurement.

Reduced Maintenance and Operational Downtime

Minimizing Downtime in Continuous Operation Systems

High-quality SCVs reduce unplanned maintenance in continuous operations. A 2025 study of mining operations found 30% fewer downtime incidents and 25% lower maintenance costs with precision-engineered valves (Mining Equipment Maintenance Report). Optimized flow regulation minimizes particulate buildup and wear, supporting reliable performance in 24/7 environments like power generation and chemical processing.

OEM and Operator Considerations in Selecting Reliable SCVs

Manufacturers are starting to prefer safety control valves (SCVs) that come with built-in wear indicators and modular components. These features let maintenance teams plan valve replacements around scheduled downtime rather than dealing with unexpected breakdowns. The adoption of predictive maintenance tech equipped with internet connected sensors has actually cut down emergency repair expenses at sea-based oil rigs by about twenty two percent over recent years. Many facility managers these days insist their valves undergo rigorous testing for over one hundred thousand operation cycles in harsh environments. Strong construction matters because when something fails in vital systems, it often leads to multiple points of failure throughout the entire network.

Strategic Suction Control Valve Selection for Optimal Performance

Matching SCV Specifications to Application Demands

SCVs must be precisely matched to application requirements. In mining, slurry-handling valves need hardened materials and high flow coefficients (Cv ¥ 12.5), while pharmaceutical systems require <2% dosing accuracy and FDA-compliant seals. Industry analysis shows 63% of premature SCV failures result from mismatched specifications in corrosive environments, highlighting the importance of application-specific engineering.

Valve Selection Based on Pressure, Flow Rate, and System Requirements

Modern SCV selection evaluates four key parameters:

| Parameter | Industrial Standard | Critical Consideration |

|---|---|---|

| Pressure Differential | 1.5 system max pressure | Cavitation risks at >85% vapor pressure |

| Flow Turndown Ratio | 30:1 for precision apps | Stable control below 10% maximum flow rate |

| Fluid Viscosity | <500 cSt standard | Need for heated jackets above 200 cSt |

| Cycle Frequency | 500k cycles baseline | Pneumatic vs. electric actuation tradeoffs |

This framework reduces installation errors by 42% in high-vibration environments, according to fluid dynamics research.

Maximizing System Efficiency Through Informed SCV Choices

Using digital twin simulations when choosing SCVs saves operators around 19% in energy costs. About 78 out of every 100 top-tier manufacturers have been doing this regularly since 2022. Getting the right SCV setup means finding a sweet spot between different factors. Electric systems respond much faster than pneumatic ones - under 50 milliseconds compared to roughly 150 ms for pneumatics. The total cost picture matters too; high efficiency models typically pay for themselves within about 18 months. And then there's scalability to consider. Modular designs let companies boost flow capacity by nearly 40% down the road without major overhauls. All these considerations together cut down commissioning mistakes by almost two thirds compared to old school approaches, which makes a real difference in operations.

FAQ Section

What is the primary function of a suction control valve (SCV) in diesel engines?

The primary function of a suction control valve in diesel engines is to manage the amount of fuel that enters high-pressure pumps, adjusting fuel input based on engine conditions to enhance fuel efficiency and reduce emissions.

What are the benefits of integrating SCVs with modern engine management systems?

Integrating SCVs with modern engine management systems allows for precise fuel control, reducing emissions and improving compliance with regulations like Euro 7 by monitoring and adjusting multiple engine parameters in real time.

How do electronically controlled SCVs improve upon traditional pneumatic systems?

Electronically controlled SCVs improve upon pneumatic systems by offering more accurate positioning, predictive maintenance capabilities, and faster throttle responses that enhance engine performance and comply with stricter environmental regulations.

What are the advantages of high-quality SCVs in fluid systems?

High-quality SCVs in fluid systems provide enhanced dosing accuracy, improved safety with reduced equipment failures, energy recovery features, and improved reliability under continuous operation conditions.

How can strategic selection of SCVs optimize system performance?

Strategically selecting SCVs tailored to specific operational conditions and requirements, such as pressure, flow rate, and material compatibility, maximizes system efficiency, reduces installation errors, and lowers operational costs.

Table of Contents

- Enhanced Engine Performance Through Precise Suction Control

- Superior Flow and Pressure Control in Fluid Systems

- Long-Term Durability and Reliability of High-Quality SCVs

- Reduced Maintenance and Operational Downtime

- Strategic Suction Control Valve Selection for Optimal Performance

-

FAQ Section

- What is the primary function of a suction control valve (SCV) in diesel engines?

- What are the benefits of integrating SCVs with modern engine management systems?

- How do electronically controlled SCVs improve upon traditional pneumatic systems?

- What are the advantages of high-quality SCVs in fluid systems?

- How can strategic selection of SCVs optimize system performance?